Innovative Solutions for Plastics Recycling

Recy Technologies designs and manufactures complete systems for sorting, separating, washing and granulating waste, using our state-of-the-art technology to achieve the best possible results at each of these stages

Innovation

These are technologies respected for their level of innovation, durability and operational reliability, reasons we are most inspired.

Sustainable development

Our research and development team is always researching revolutionary technologies and new models of sustainable development, producing products with more energy-efficient technology and water sustainability.

Environmental sensitivity

The problem is not the waste but how it is managed: proper information and education on its use and recycling would safeguard our planet and consequently improve everyone’s lives.

If you would like to know more or would like us to provide a quote? Please contact us

All machines are made and manufactured at Recy Technologies S.R.L in Italy – https://recytechnologies.it/en/

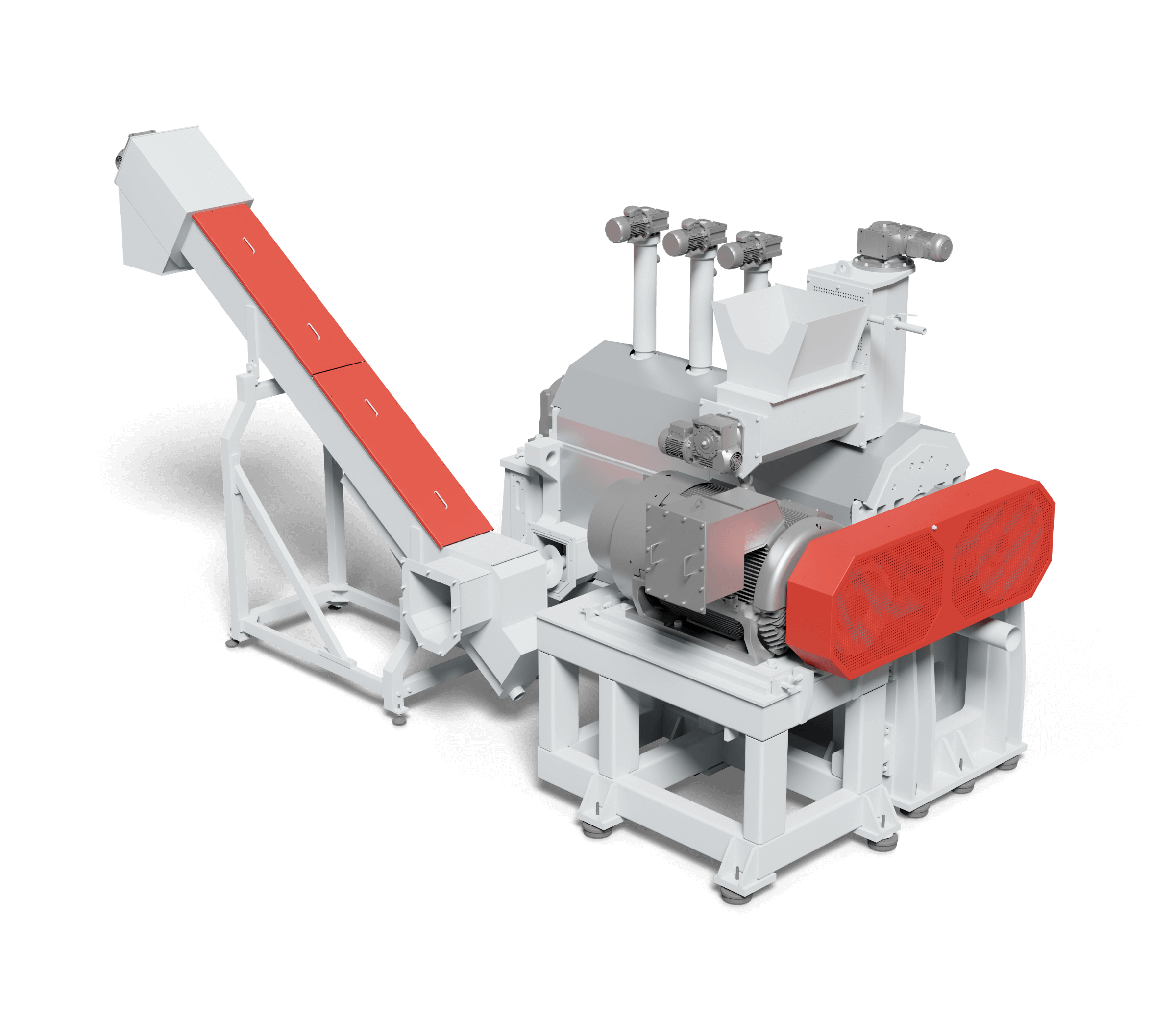

The purpose of the machine is not just traditional drying of the material, but drying combined with preparation of the treated products for the

extrusion process up to the densification of flexible materials. It replaces all traditional drying systems

TECHNICAL FEATURES;

• Loading forcer for better material entry

• Control of the dwell time of the material inside the machine

• Temperature and humidity adjusted according to product requirements managed by special software

• Bearing supports designed with special cooling circuit

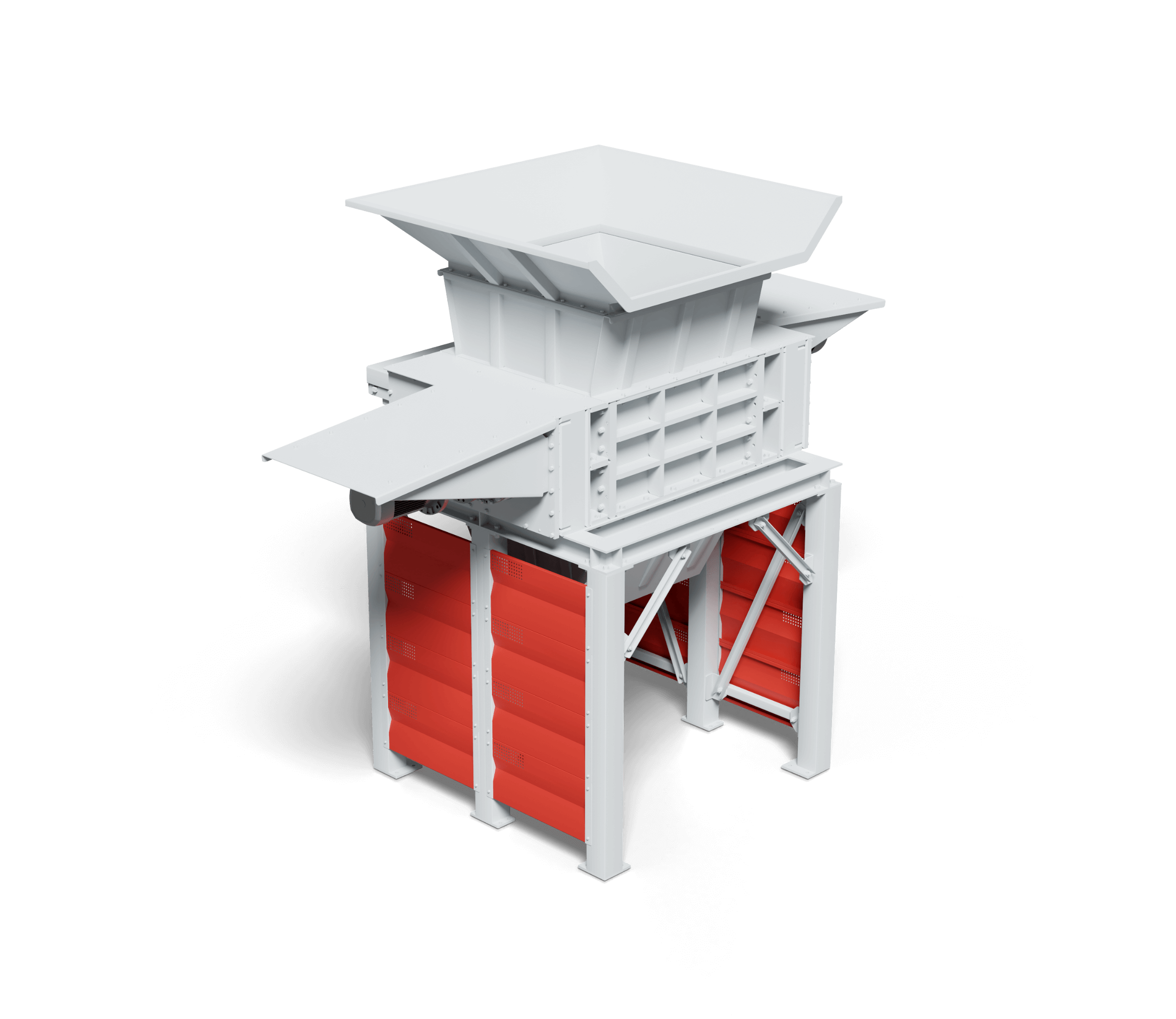

The machine opens the bags from urban and industrial collection without damaging the contents, thus preserving the integrity of the

materials to be treated

TECHNICAL FEATURES;

• Self-cleaning system in case of blockage

• Single motorization for each rotor.

• Automatic temporary accumulation system to ensure a constant flow to the line even with irregular loads or automatic start

• Modularity of the rotor groups for maximum adaptability to the product

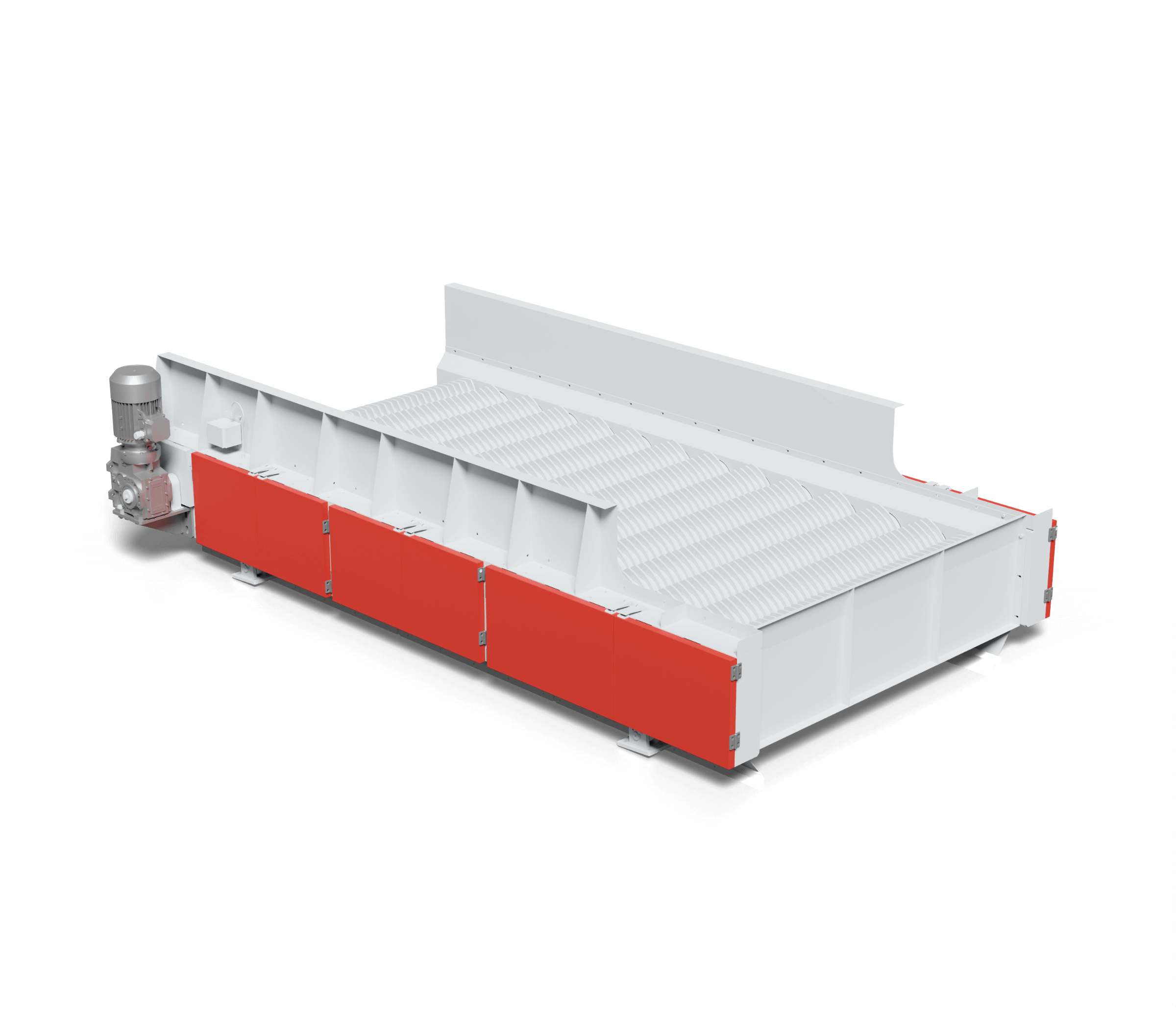

The purpose of the machine is the storage and dosing of material to ensure the correct flow of the product to be processed to the

line, thus going to optimize its efficiency. The stored light (flexible) material is easily unloaded without creating the “bridge” effect

TECHNICAL FEATURES;

• Uniform dosing of material by augers under inverters

• Electronic level control system with minimum and maximum warning

• Modular design to ensure maximum operational efficiency

• Maximum energy efficiency

The machine is designed down to the smallest detail to ensure maximum screening capacity with all types of products, from industrial to urban waste,

managing their sizes and types

TECHNICAL FEATURES;

• Different disc profiles according to the material to be processed

• Maximum flexibility in the size of the material to be screened due to customizable disc spacing

• Adjustable tilt for maximum screening accuracy

• High material throughput

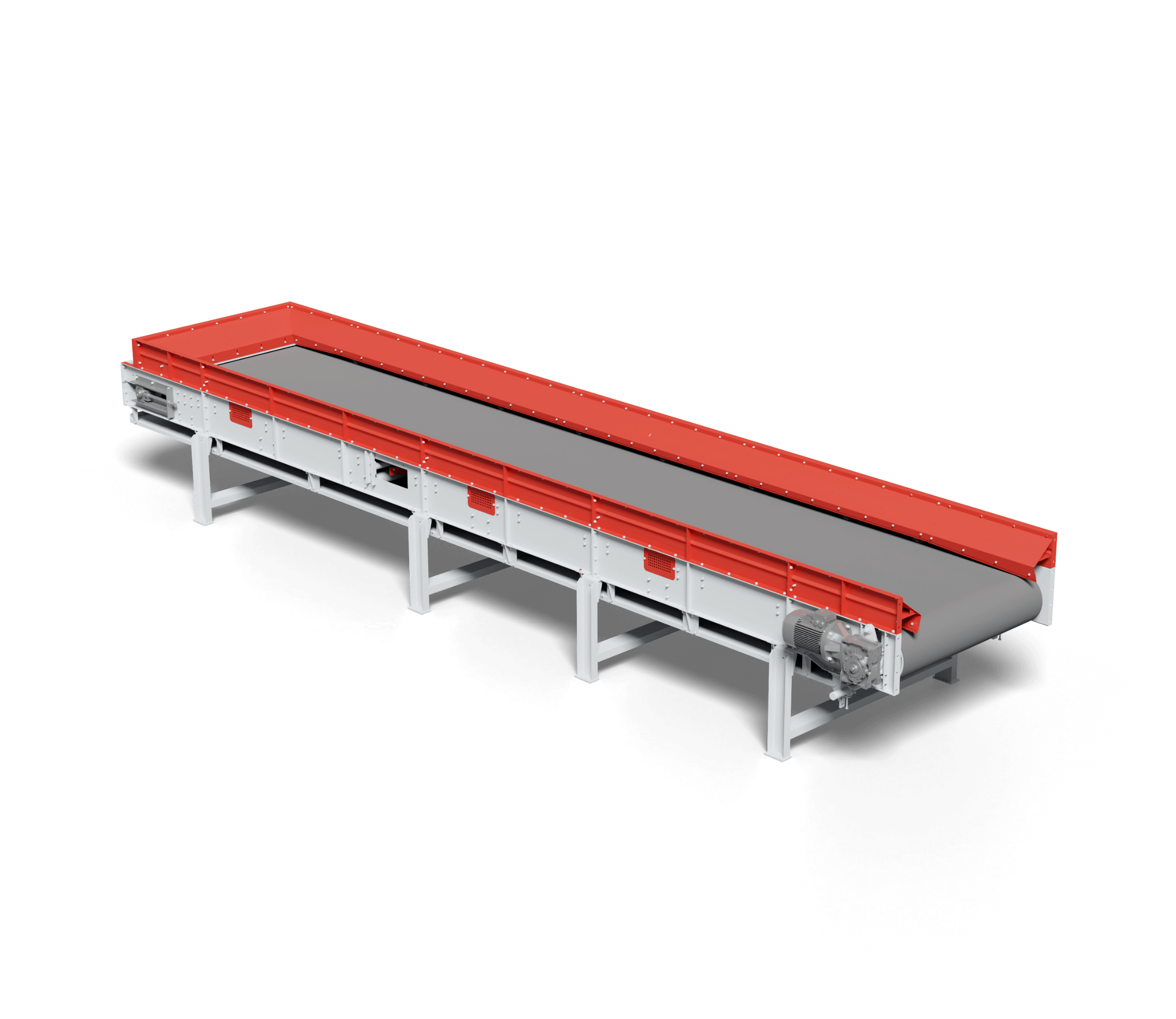

The purpose of the conveyor belt is to transport different materials within plants. Depending on the need, it is made in various

executions for maximum adaptability to the products to be conveyed and the plant in which it is placed

TECHNICAL FEATURES;

• Sturdy supporting structure on adjustable feet for easy positioning

High-strength rubber mat

• Material containment side bulkheads • Execution in different modes depending on the products (concave, flat, rubber, with porters, rolling shutters, knee, etc)