Some key advantages, as you hopefully consider, for this up coming investments

- Much Lower Power Consumption – CHEAPER POWER BILLS !!

- Smaller Chiller with respect to the hydraulic machines (the cooling is required only for the mould)

- Very low consumption, mainly in the dry cyclesConstant and continuous (repeatability) of the cycles because we are not depending of the variations of the hydraulic oil;

“friendly” management of the machine by the operators, even during the maintenance. - Wide range of container products.

- Several accessories and processes available: “ View Stripe”, co-extrusion and multilayer, IML, etc.

- Very clean operation – Clean room possibilities : No Oil !

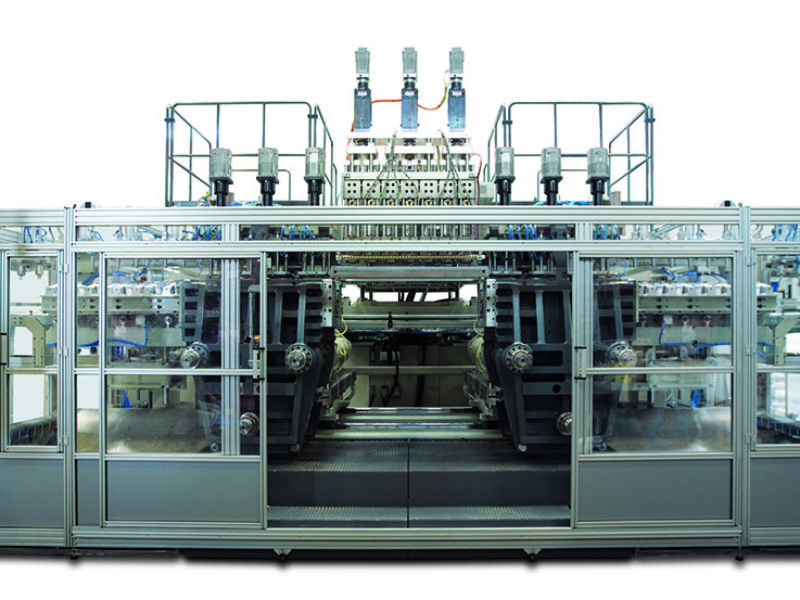

Today, with the ME series we are in the second generation and with the most complete worldwide range of models:

- 18 models and approx. 5 versions for each model;

- Max volume container 2 x 25 lt with double head (c.d. 340 mm) or 50 lt in single cavity;

- Max clamp force available (on b.m. model machine ME-L30-40/….ND (single shuttle) or D (double shuttle): 500 kN (50 tonne.)

- The ME series work with “recuperating energy system”; in fact the energy accumulated during the phase when the motors are braking, is later re-generated and put into the circuit.